|

Getting your Trinity Audio player ready...

|

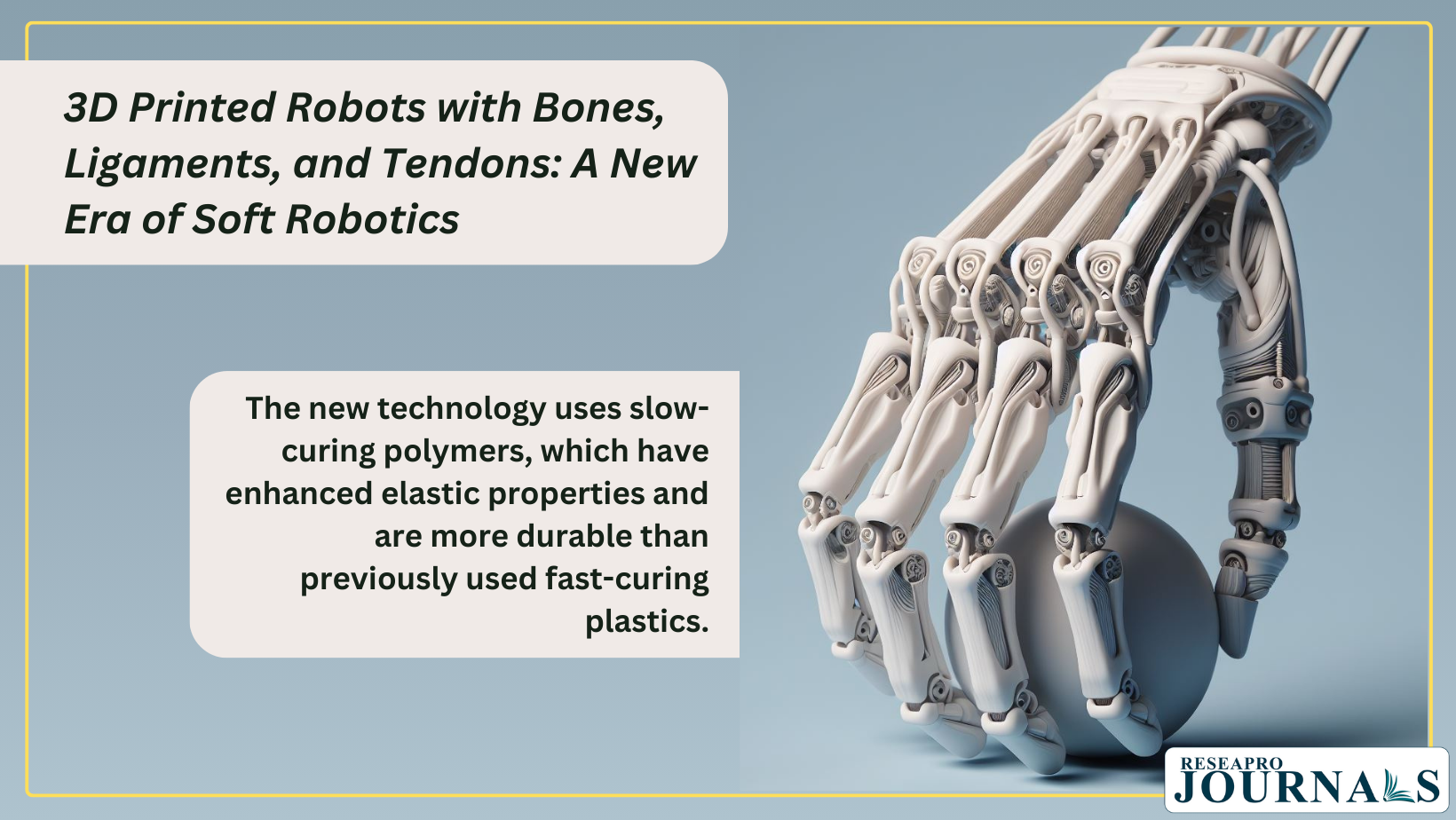

Get ready for a revolution in robotics! Researchers at ETH Zurich and a US start-up have developed a new technology that makes it possible to 3D print robots with bones, ligaments, and tendons, all in one go. This breakthrough opens up completely new possibilities for the production of soft robotic structures.

The new technology uses slow-curing polymers, which have enhanced elastic properties and are more durable than previously used fast-curing plastics. This makes it possible to create robots that are more flexible, lifelike, and safe to work with humans.

Soft robots have several advantages over traditional robots, including:

- Safety:┬ĀSoft robots are safer to work with humans because they are not as rigid and can conform to different surfaces.

- Dexterity:┬ĀSoft robots can be more dexterous than traditional robots because they can bend and flex in ways that are not possible with rigid robots.

- Versatility:┬ĀSoft robots can be used in a wider range of applications than traditional robots because they can be adapted to different environments.

The researchers believe that this new technology has the potential to revolutionize a wide range of industries, from healthcare to manufacturing. Here are just a few potential applications:

- Healthcare:┬ĀSoft robots could be used to perform delicate surgeries,┬Āassist with rehabilitation,┬Āand provide companionship to patients.

- Manufacturing:┬ĀSoft robots could be used to perform tasks that are currently difficult or dangerous for humans,┬Āsuch as handling delicate materials or working in hazardous environments.

- Consumer Products:┬ĀSoft robots could be used to create new types of toys,┬Āappliances,┬Āand wearable devices.

The development of this new technology is a major step forward in the field of robotics. It is clear that the future of robotics is soft, flexible, and lifelike.